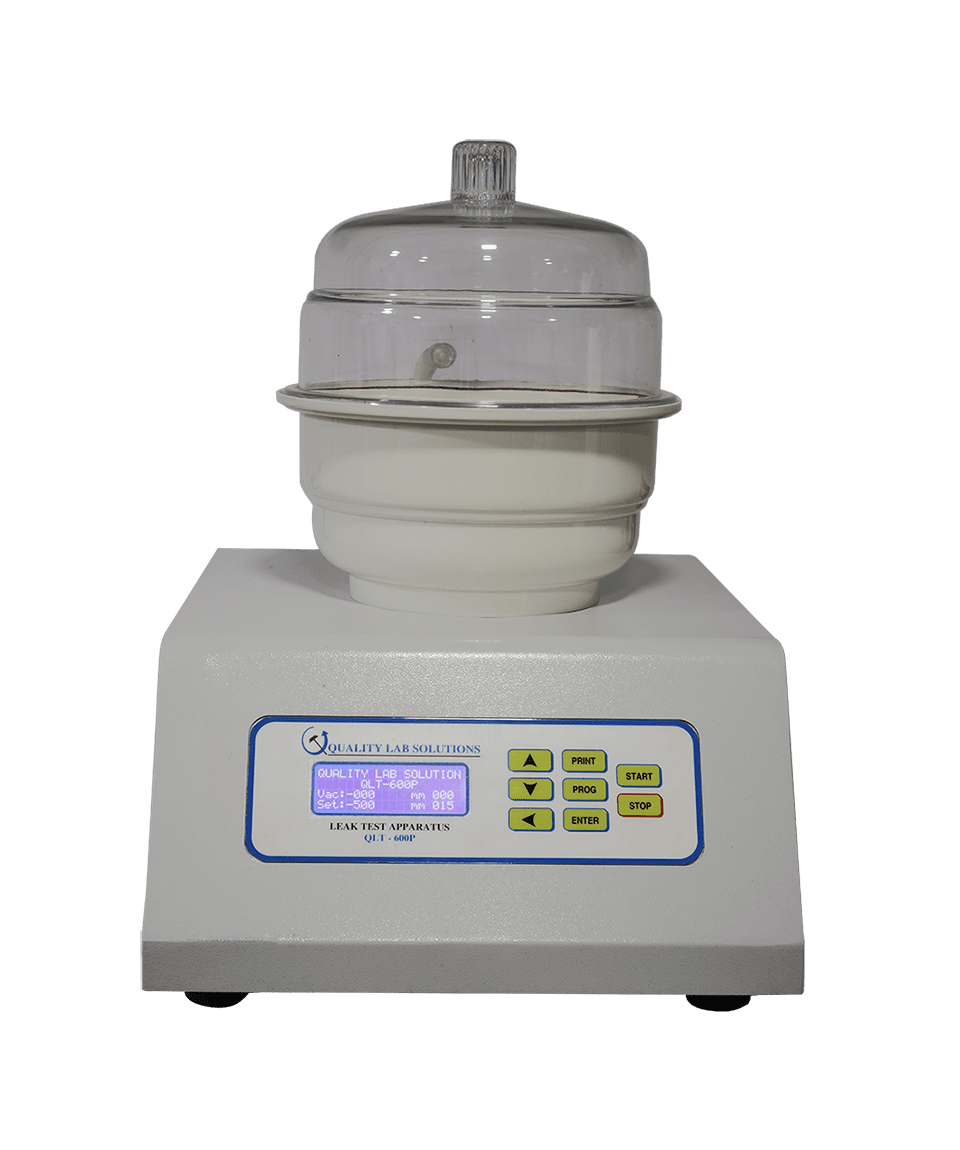

Overview

The QLT-600P is used to test for the integrity of packed strips, blisters and small sachets containing tablets, granulates, liquids and so on. The instrument is used to test the quality of the packaging process and to check that the seals enclosing the product are perfectly intact. The QLT-600P leak tester is designed to find the smallest holes and imperfections in blister packs and other semi-rigid product packaging. It is designed in compliance to the USP monograph (1136).

Test Procedure The leak test apparatus is widely applied in the pharmaceutical industry for checking strips, blisters and bottles containing tablets, capsules, syrups and so on.Read More...

It also find application in the food industry where it can be effectively used to check the air-tightness of sweet packets, ready-to-eat pre-packed foods, confectionery packaging, packs of noodles, sauces to name but a few. Samples are placed into the desiccator’s housing and the lid is placed in position. The pump starts to produce a vacuum inside the desiccators and the vacuum is held for a pre-set time.

FEATURES

Meets USP And Package Specifications.

Ideal For Checking Leakage Of Packed Strips, Blisters, Small Sachets And Ampoules.

Fully Automatic System.

Display indicates set and actual vacuum level.

Vacuum level can be set up to 600mm of Hg.

Programmable retention time, start delay time and vacuum hold time.

Automatic release of vacuum at the end of the test.

Oil-Less Vacuum Pump.

Alarm indication to indicate the status if the test.

Incorporated with an oil free vacuum pump.

Read AllStainless steel body.

Compact size makes the device portable.

Slow release of vacuum at the end of the test.

Slow Venting For Better Results.

Serial interface of vacuum at the end of the test.

Serial interface to attach dot matrix printer.

Validation Report Printout.

Polycarbonate vacuum desiccator.

20X4 LCD display.

Specification

Vacuum Level : > 650mmHg

Vacuum Setting : Vacuum can stabilize for a set value from:

Display : 20X4 LCD DISPLAY

Data Entry : Function key

Timer : Can be set from 1 to 99 minutes

Desiccator Sizes : 300mm, 250mm, 200mm or 150mm Ø (optional)

Printer : Parallel port for dot-matrix printers

Power : 230V.50Hz

Instrument dimensions : Approx. 400 x 240 x 220 mm (Length x Width x Height)

Net weight : Approx. 17kg

Certification : All components certified to USP / EP requirements

Validation : All IQ & OQ documents included

Parts & Accessories

12 mm Round Glass Plate for 250 mm Dia Desiccator (Part No : QLT20060) (QTY = 1)

12 mm Round Glass Plate For 300 mm Dia Desiccator (Part No : QLT20061) (QTY = 1)

Vacuum Desiccator Of 250 mm Dia With Perforated Disc For 250 mm (Part No : QLT20062) (QTY = 1)

Vacuum Desiccator Of 250 mm Dia With Perforated Disc For 250 mm (Part No : QLT20063) (QTY = 1) .

IQ/OQ Documents (QTY = 1)

Downloads Product catalogue

LEAK TEST APPARATUS-QLT–600P

The QLT-600P is used to test for the integrity of packed strips, blisters and small sachets containing tablets, granulates, liquids and so on.

Download Now