Overview

Friability testing is used to test the durability of tablets during packing processes and transit. This involves repeatedly dropping a sample of tablets over a fixed time, using a rotating drum with a baffle. The result is inspected for broken tablets, and the percentage of tablet mass lost through chipping.

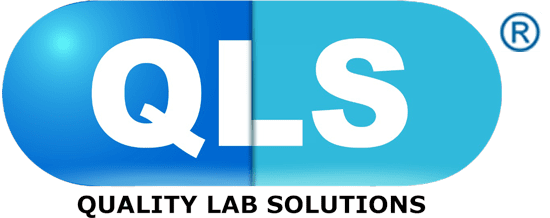

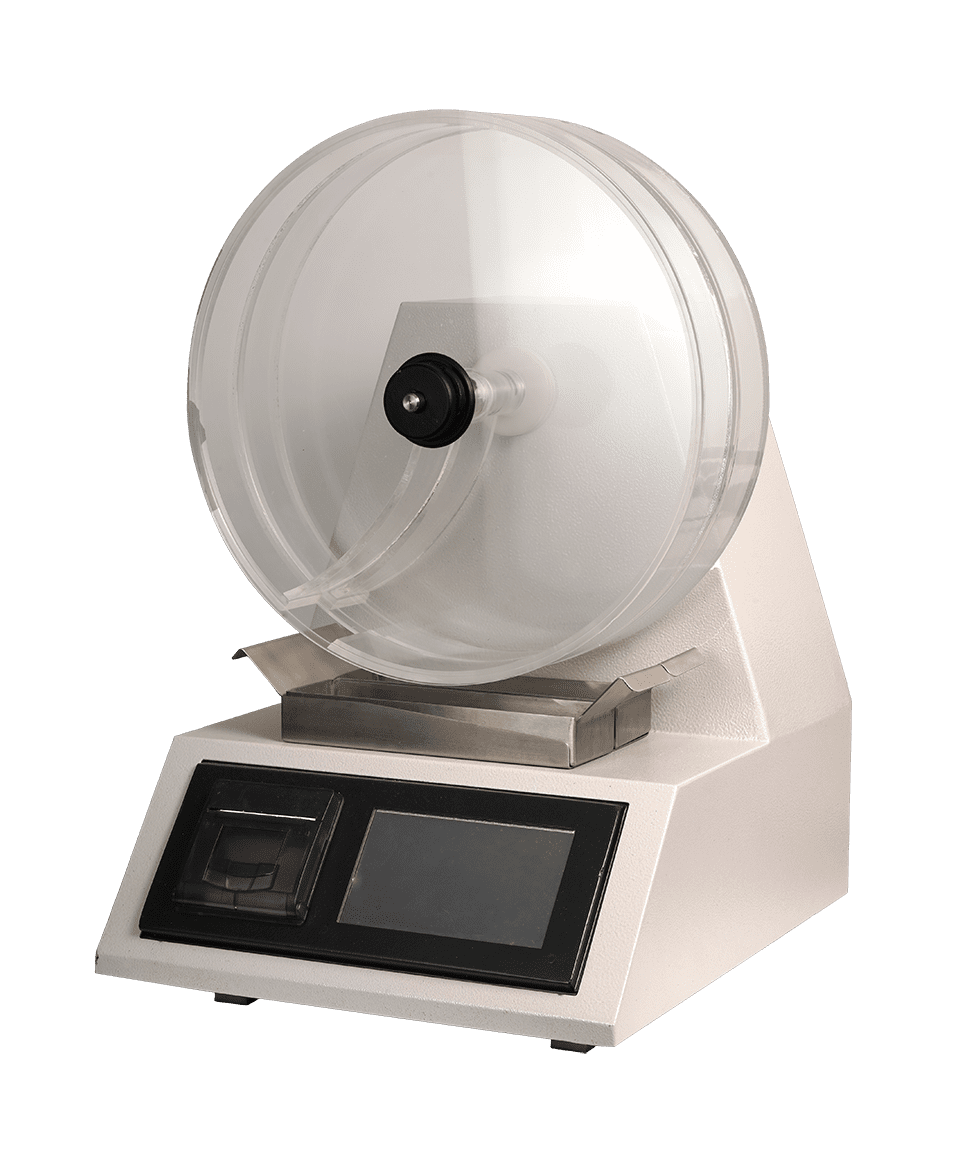

QFR 200 is a Double drum tablet friability and abrasion test instrument. It is manufactured in compliance to the USP (1216), EP (2.9.7) and JP (14) Pharmacopoeias.

The instrument features an automated sample discharge at the end of a test and the possibility to connect an analytical balance.

FEATURES

Fully USP (1216), EP (2.9.7) and JP (14) compliant.

5’’ TFT LCD WITH TOUCH SCREEN.

Auto Unloading By Rotating in Reverse Direction.

Determine friability and abrasion (optional) of uncoated tablets.

Programmable for number of drum revolutions or rotating time.

Connect a balance to determine the sample weight (optional, weight can be entered manually).

Connect to RS485/232 Port to copy methods and store test reports.

Integrated protocol printer (optional).

Read AllUser and method management system.

Optional Abrasion Drums.

Optional 10 Degree Angle Stand.

Specification

Drums : Acrylic ,two numbers

Display : 5’’ TFT LCD with touch screen.

Parameters : Time, Count

Unit Time : Hour, Minute and Seconds

Rpm Control : Microprocessor controlled stepper motor

10° Stand to Test Large Samples

Rpm Range : 20 to 50 rpm

Rpm Accuracy : ± 1% of full scale

Rpm Resolution : 1%

Timer Range : 1min to 999min

Timer Accuracy : 0.1%.

Count range : 001 to 999

Count accuracy : ±1

Printer : Connectivity through RS232/485 port. serial / Dot matrix

Power Requirement : 230VAC 50/60Hz 5A./110VAC 50/60Hz 10A

Dimensions (L x W x H) : 350 x300x450

Weight : 10kg

Validation Documents : IQ/OQ Documents

Parts & Accessories

Included in the Standard Scope of Supply

One friability drum made from Plexiglas (optional incl. anti-static coating), in compliance with the USP, EP and DAB pharmacopoeia Comprehensive documentation included (PDF, hardcopies optional):

One friability drum made from Plexiglas (optional incl. anti-static coating) (Part No : QFT20047)

Compliance with the USP, EP and DAB pharmacopoeia (Part No : QFT20048)

User manual

DQ/QC instrument compliance test certificate

IQ documentation

OQ documentation

Instrument logbook

Compliance certificates

Optional Accessories

Friability drum with anti-static coating (Part No : QFT20041)

Tablet abrasion drum with lamellas (Part No : QFT20042)

10° stand to test large samples (Part No : QFT20043)

Internal thermal printer (Part No : QFT20044)

Certified calibration tools (Digital Vernier, Angle Measuring Tool ,Stop Watch) (Part No : QFT20045)

Tablet Collection Tray(Part No : QFT20046)

Downloads Product catalogue

FRIABLITY TESTER QFR 200

Friability testing is used to test the durability of tablets during packing processes and transit.

Download Now